-

Heat Shrinkable Products

-

Heat Shrinkable Rolls

Heat Shrinkable Rolls:

Heat Shrinkable Rolls: -

Heat Shrinkable Sleeve for Plastic Drainage Pipeline

Heat Shrinkable Sleeve for Plastic Drainage Pipeline:

Heat Shrinkable Sleeve for Plastic Drainage Pipeline: -

3PE Heat Shrinkable Tape (Sleeve)

3PE Heat Shrinkable Tape (Sleeve):

3PE Heat Shrinkable Tape (Sleeve): -

Fiberglass Reinforced Heat Shrinkable Tape (Sleeve)

Fiberglass Reinforced Heat Shrinkable Tape (Sleeve):

Fiberglass Reinforced Heat Shrinkable Tape (Sleeve):

-

Heat Shrinkable Rolls

-

Electro Fusion Products

-

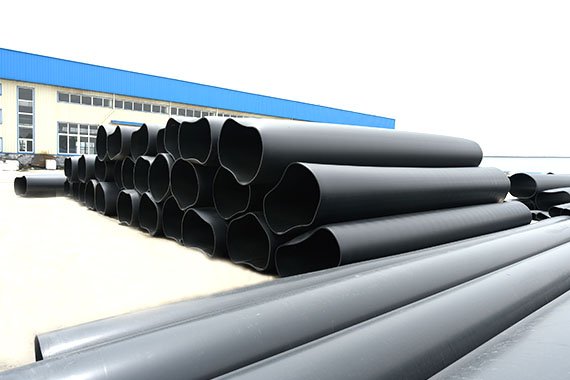

PE Electro Fusion Welding band for Steel Reinforced HDPE Spiral pipes

PE Electro Fusion Welding band for Steel Reinforced HDPE Spiral pipes:

PE Electro Fusion Welding band for Steel Reinforced HDPE Spiral pipes: -

PE Electro Fusion Welding band for Plastic Hollow Wall Spiral Pipes

PE Electro Fusion Welding band for Plastic Hollow Wall Spiral Pipes:

PE Electro Fusion Welding band for Plastic Hollow Wall Spiral Pipes: -

PE Electro Fusion Welding Sleeve for Pre-insulated pipes

PE Electro Fusion Welding Sleeve for Pre-insulated pipes:

PE Electro Fusion Welding Sleeve for Pre-insulated pipes:

-

PE Electro Fusion Welding band for Steel Reinforced HDPE Spiral pipes

- Plastic Welder

- Plastic Products

- News

- Honor

- FAQ

一級(jí)標(biāo)題

一級(jí)標(biāo)題